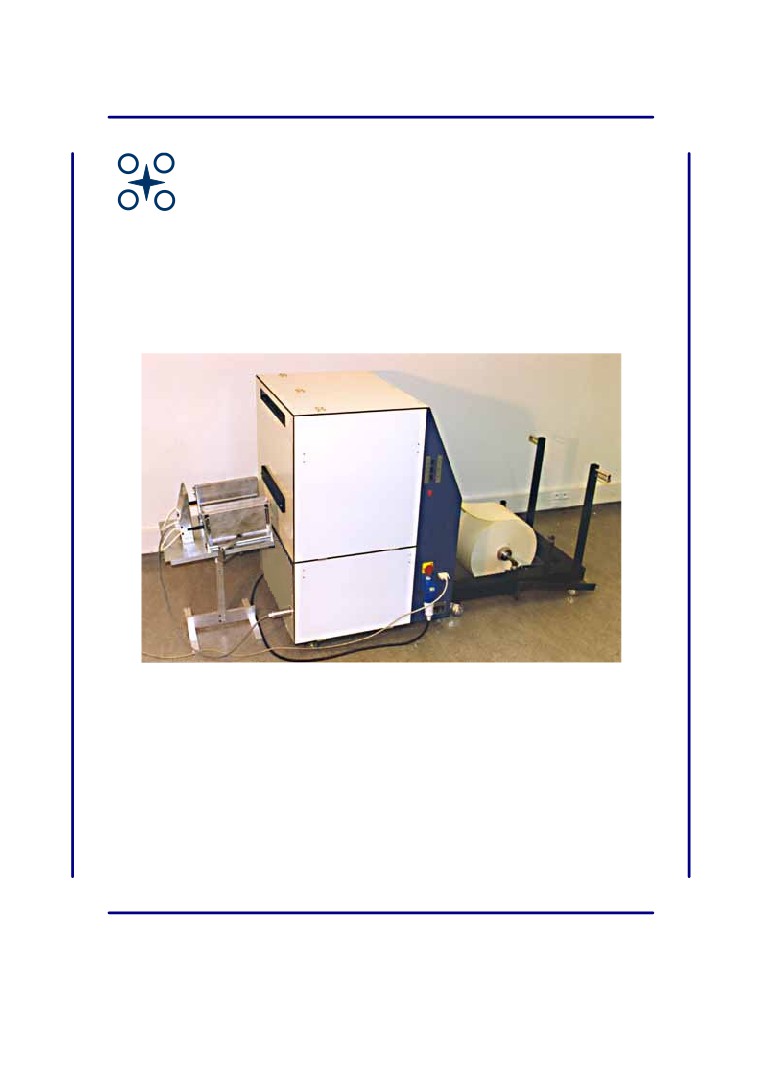

Interpoint 55

Electronic Braille Embosser

Designed for reliable, economical,

practical and high-quality Braille production

©2008 INTERPOINT N.V. BELGIUM

The Interpoint 55 electronic Braille embosser has been designed for reliable, economical

practical and high-quality Braille production. The embosser is computer controlled and easy

to operate. In the design, special attention was given to productivity, quality and safety of

operation.

PRODUCTIVITY

Economy of paper

The Interpoint 55 embosses text on plain paper

from reels without tractor feed, folds or

perforations. This saves paper as no pin feed holes

are needed. After embossing, pages are cut to the

correct width by a sturdy yet simple built-in cutting

mechanism.

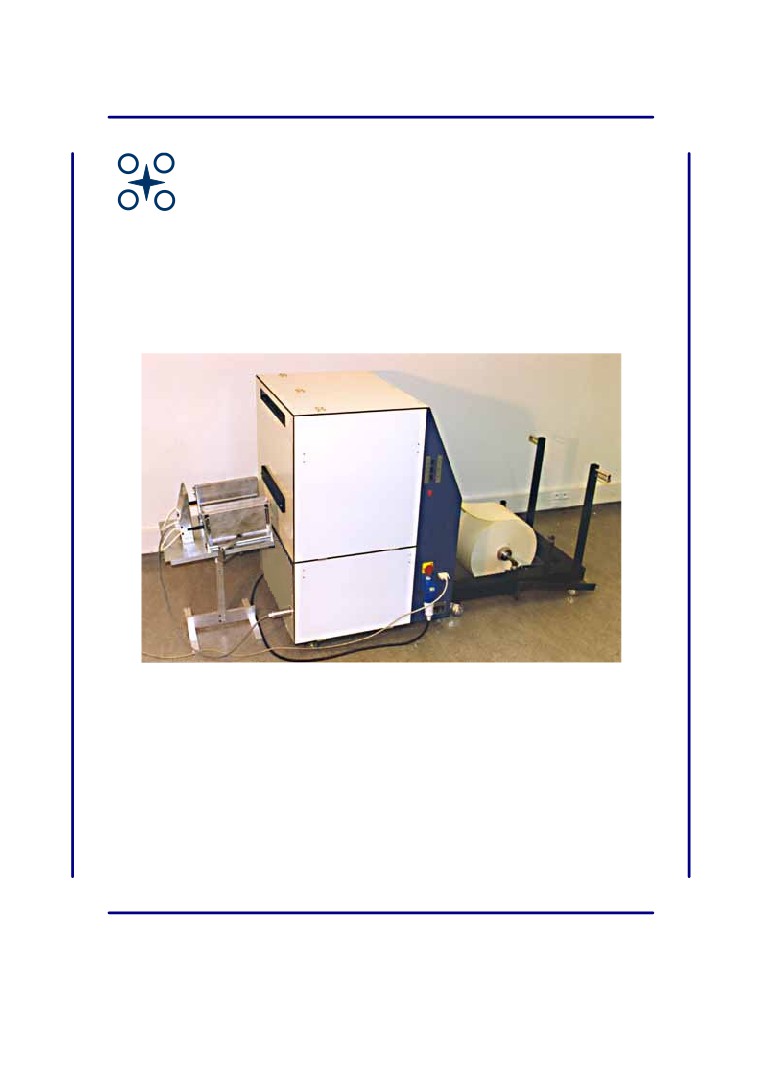

Paper on reels tends to be curved more towards

the center of the reel. The Interpoint

55 has a

built-on decurler that makes the curved paper flat

again before embossing. This allows using all of

the paper on the reel.

Economy of operation

The Interpoint 55 embosser is computer controlled. Immediately after the text is put on the

computer, the printing can be started. Multiple copies of a document can be printed one at a time

so that no collating of pages is needed afterwards.

High production rate

The Interpoint 55 prints up to 800 characters per second in 6-dot Braille which amounts to 2000

pages A4 per hour.

QUALITY

Mechanical quality

The Interpoint 55 is characterized by having few moving parts. Mechanical wear is highly reduced

by the design principle of the moving matrix: moving parts are free of stress, parts under stress

stand still.

Electronics quality

Computer-designed printed circuits and oversize power components give longer life. The

electronic reliability of the Interpoint

55 embosser is enhanced by high efficiency and cool

operation.

Embossing quality

The relief produced by the Interpoint 55 is of high quality. Braille dots are nicely round shaped,

have constant height and are perfectly aligned in a fixed matrix with basic cell size of 2.5 mm.

This relief is stable and does not require adjustments over the entire interval of service.

SAFETY

The electronic circuits are fed from a low voltage transformer and thus effectively insulated from

the mains. All doors are equipped with safety interlocks. The cutting device and motor belts are

shielded.

PAGE FORMAT

Sideways printing

The Interpoint 55 embosser introduced the principle of sideways embossing. With sideways

embossing, a page is printed column by column from left to right, instead of top to bottom.

Starting from reels of continuous paper, a page can therefore be as wide as needed; there is no

mechanical limitation on the maximum number of characters printed on a line.

Interpoint

The Interpoint 55 embosser can print both single sided (Recto or Verso) and double sided Braille

(Recto/Verso).

Output page format

The output page format is software defined. The

build-in cutter will cut the paper to single pages

or double pages (magazine style). In magazine

style, there are 4 text pages on a sheet, with a

programmable fold pattern in the middle of the

sheet to make the folding of the sheet easier. In

magazine style, our driver software can split a

book automatically in quires (signatures).

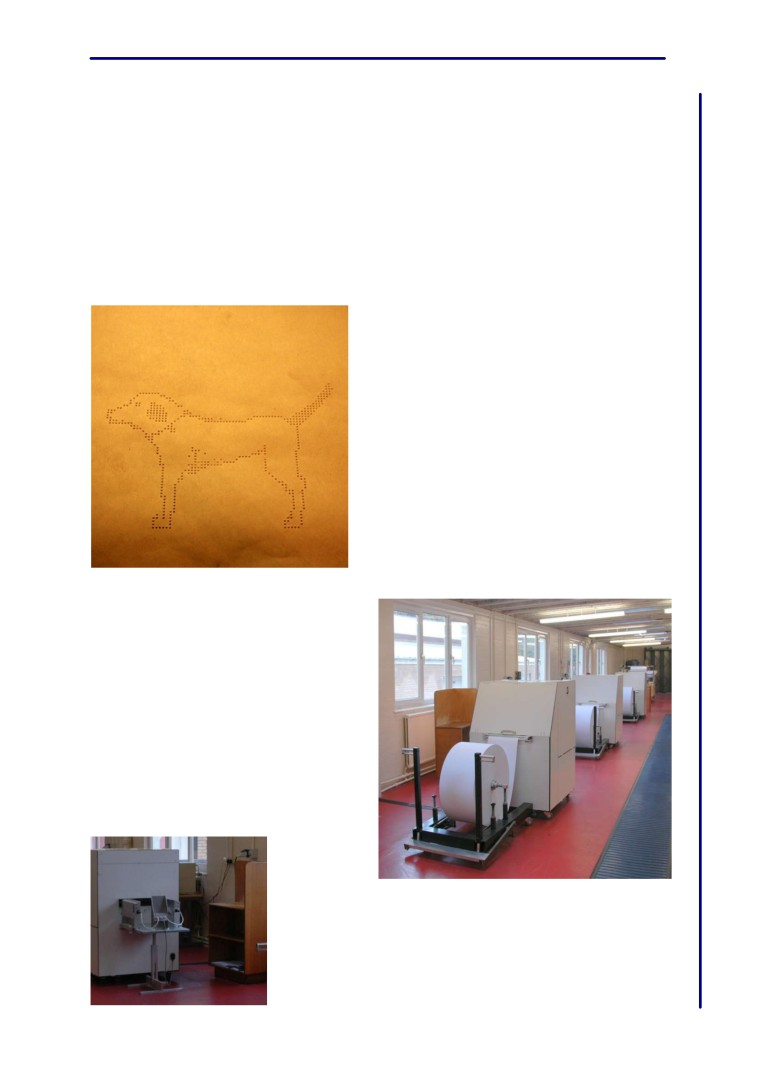

Graphics

The Interpoint

55 embosser is a graphical

embosser, printing dots on paper or plastic. The

software determines which dots are printed

where, making it possible to print graphics and

larger spaced Braille (jumbo) as well as Braille.

ACCESSORIES

Paper Cart PK55

The Paper cart type PK55 is able to carry

reels of paper of up to 1 meter diameter.

Smoothly rolling on wheels, the cart can

be moved around to pick up a reel of

paper and position it in front of the

Interpoint 55 embosser. Mounting paper

reels onto the PK55 is easy: by a simple

step on the foot pedal, even heavy paper

reels are lifted in a fraction of a second

without effort.

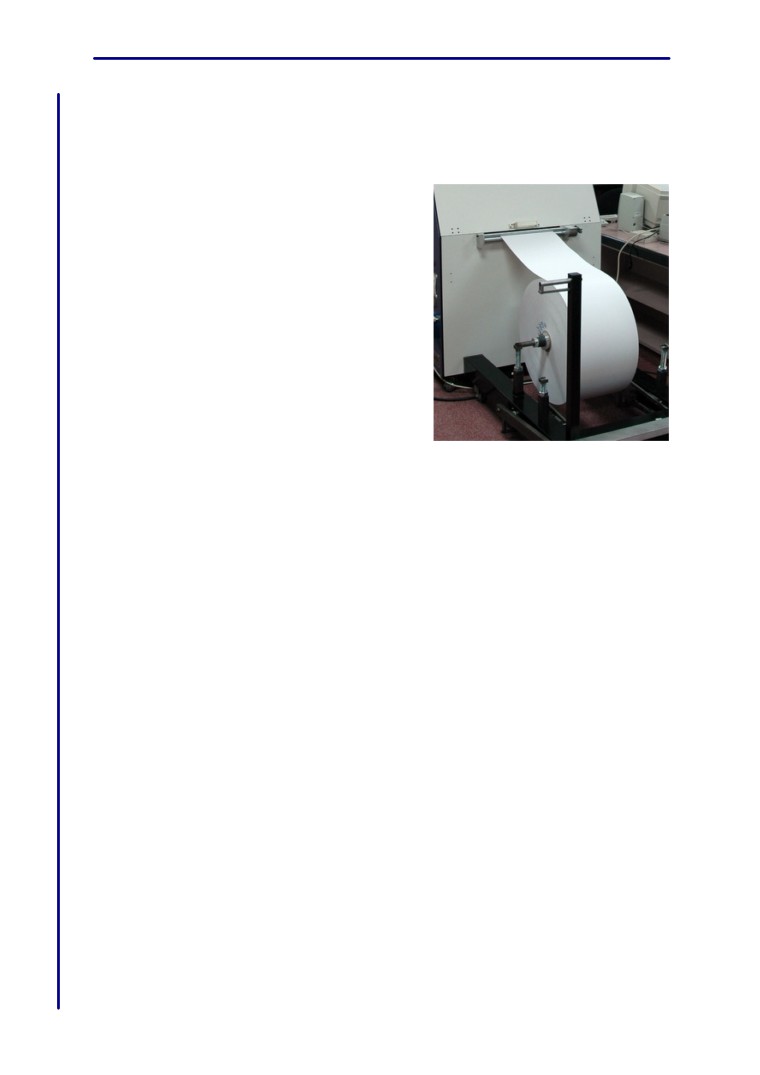

Paper Reception Stacking Table

The Paper Reception Stacking Table will handle the output of

the Interpoint 55 electronic Braille embosser. When the book

is printed, the operator can take the book from the stacking

table. Printed books are ready for binding or folding and

stapling.

Interpoint 55 technical specifications

Printing speed

25 strokes per second which can result in up to 800 characters per second in 6-dot Braille or

2000 pages A4 per hour.

Page format

Software defined:

- number of characters per line: max. unlimited

- number of lines per page in 6-dot Braille: max. 32

- programmable margins

- Single sided or double sided Braille

- Single pages or Magazine style (4 pages to a sheet with programmable

fold pattern, automatic book division in quires (signatures) possible)

Braille cell and dot size

Dot diameter

: 1.5 ± 0.1 mm

Cell dot distance

: 2.5 mm

Character spacing

: programmable, default 6.3 mm

Line spacing

: - 6-dot Braille: 10 mm

- 8-dot Braille: 12.5 mm

Braille paper : Reels on core, no pin feed, no perforations, no folds

Specific weight

: 120 to 200 g/m²

Core opening

: 60 to 80 mm (70 is standard)

Diameter of reels

: max. 1 m

Width of reels

: max. 34 cm

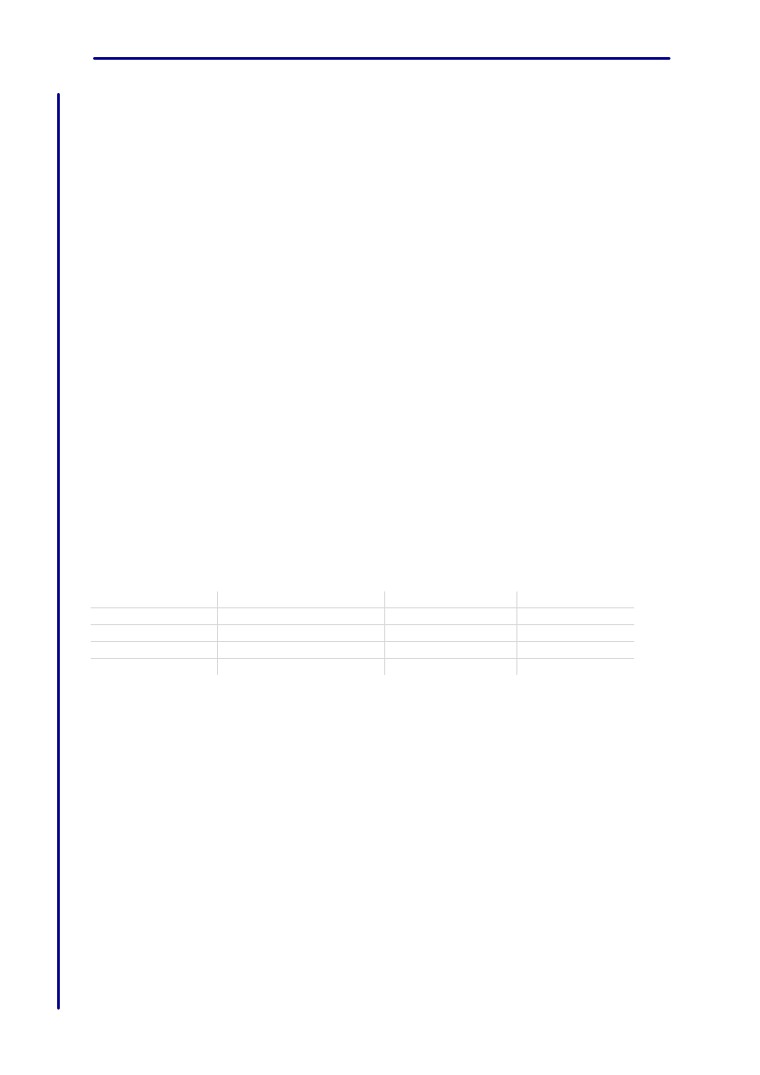

Physical characteristics

Embosser Interpoint 55

Paper Cart PK55

Stacking Table

Height

140 cm

92 cm

83 cm

Width

92 cm

77 cm

60 cm

Length

110 cm

114 cm

60 cm

Weight

± 270 kg

80 kg

20 kg

Power Supply

207/220/230V ± 5%, 50/60 Hz, 10A single phase fused at 20A

Noise level

Standby

: Silent

Printing

: 78 dbA

Data transmission

Interface

: RS232C Serial 25-pin female connector.

or USB through USB to Serial adapter.

Baud rate

: 19200

Other possible rates: 9600, 7200, 4800, 3600, 2400, 1800, 1200, 600,

300, 150, 134.5, 110, 75 and 50 baud

The manufacturer reserves the right to change specifications at any time without prior notification.

Tel/Fax: +32 16 20 12 30, Email: interpoint@interpoint.be, Website: www.interpoint.be